Starting about 20 years ago, there was a lot of interest, excitement, hype, and promise that power–transmission lines using superconductors rather than conventional copper or aluminum conductors would be coming soon, resulting in dramatic reduction of losses in these lines. Estimates were that about 5% to 10% of the power sent through these liens is dissipated due to ohmic resistance, and while that’s not a huge number, it is still high enough that any significant decrease — especially down to near zero using superconductors — would be a big plus with respect to basic efficiency and other beneficial attributes.

Why the concern about passive transmission lines? These lines are one of the three “legs” of the bigger power picture, along with generation and storage (Figure 1). Whether the power comes from a remote coal–, oil–, or gas–fired station or from renewables such as wind, wave, geothermal, or solar farms, there’s a need to send that generated power to the load. (Be careful with terminology here: This “transmission line” has no relationship at all to an RF transmission line, of course.)

While highly localized power sources, such as a neighborhood or personal wind or solar arrangement with a “private” power–management system and storage batteries, don’t need long– or even medium–distance lines, most power systems and users do. These conductors are sophisticated systems with various performance and thermal monitors, provide protection against surges and lightning, must deal with potential corona discharges, and have many other considerations that belie their apparently simple functionality.

Superconducting transmission lines offer another likely benefit. In addition to greatly reduced losses, these lines have smaller diameters; can use smaller, less intrusive towers; and are possibly a solution to running high–power lines in dense urban areas, where there is insufficient space for the physically larger conventional cables.

The phenomenon of superconductivity is not only limited by temperature but also by the electric current density and the magnetic field the material is exposed to. If any one of these three parameters exceeds a critical value, then superconductivity vanishes, and the material behaves like a normal conductor (a pretty bad one, in the case of high–temperature superconductors). Still, under the right conditions, a superconductor can handle current densities about two orders of magnitude greater than possible with conventional conductors.

The big breakthrough for the more practical implementation of these powerlines is the development of so–called high–temperature superconductors (HTSes or HTSCs). Unlike previous superconductors, which required costly and complex helium–based cooling down to a few kelvins, the HTS only needs to be cooled to 77 K, which brings two advantages: It can be done with plentiful liquid nitrogen, and obviously, it’s easier to cool down to 77 K than the helium value of 4 K. In contrast, niobium–titanium (NbTi) only becomes superconductive below 9.4 K, requires liquid–helium cooling, and is very difficult to manufacture and make into cables.

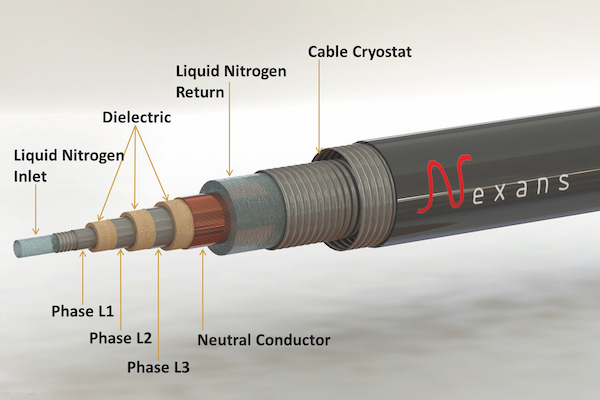

Due to the availability of these HTSCs, a few demonstration projects were installed over modest distances to test the concept. One example is the AmpaCity project in downtown Essen, Germany, in operation since 2004. The 1–km AC cable (Figure 2) provided by Nexans is based on high–temperature ceramic superconducting materials with a three–stage design that maintains a constant flow of coolant both inside and outside of the conductive material.

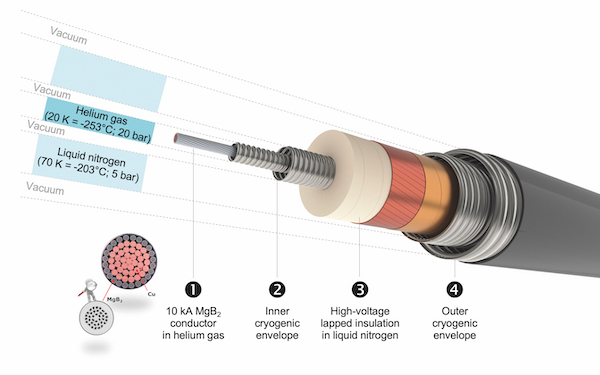

Another promising candidate for superconducting power lines is magnesium diboride (MgB2), which is based on raw materials that are abundant in nature. One source stated, “It is easy and inexpensive to manufacture on a commercial basis, making it much cheaper than existing superconductor materials.” (I guess it’s all relative; I would never use the words “easy” and “inexpensive” in relation to any superconducting material or cable.)

However, unlike ceramic HTS materials , MgB2 has a drawback: It needs to be cooled to lower than 25 K. This requires more complex and more expensive cooling systems rather than just liquid nitrogen. A cable built using this material uses an inner cryogenic envelope cooled by helium gas at 20 K, with an outer envelope that is cooled by liquid nitrogen at –276 K (Figure 3).

There are some other demonstration projects using superconducting power lines with both low– and high–temperature superconductors, but there hasn’t been much reported about them. Are the technical issues of fabricating and installing the cable and the cooling requirements just too challenging for widespread application?

Superconducting is widely used in applications as unique as the Large Hadron Collider and other particle–physics accelerators, and even as mainstream as medical magnetic resonance imaging (MRI) systems that require intense magnetic fields on the order of several Tesla to provide crisp images. But those are well–defined installations with known and constrained sources and loads, in predictable and controlled environments. Perhaps the rough–and–tumble world of longer–distance power transmission just isn’t a good fit for superconducting, supercooled cables? Maybe the gain is just not worth the cost and pain of installation, routine maintenance, and unplanned outages and repair?

What do you think is the future of power transmission using any superconductor that requires cooling? Will we have to wait for so–called room–temperature superconductors that do not need any cooling — if they ever come? One thing is for sure: A high–voltage/high–power cable is conceptually simple, but the reality is that any such cable, whether it is conventional copper/aluminum or superconducting, is much more sophisticated and complicated than that concept.