Electronic systems’ power requirements have become quite demanding, and designers face sequencing problems, with the opportunity to meet various voltage requirements and minimize thermal effects.

The combination of Dialog’s flexible and scalable GreenPAK technology with TDK’s DC Point of Load (POL) modules offers a compact solution for powering advanced embedded, IoT, and 5G industrial control applications. The combination of these two technologies is particularly suitable for high-density industrial computing applications.

Speaking to EE Times Europe, Applications Engineering Director at Dialog Semiconductor, Ramzy Ammar, said, “Power Sequencing requires a lot of discrete components to take care of the sequencing if it involves multiple rails power up and power down. These require more components like resistors capacitors, Analog Comparators, and logic blocks to detect a rail’s integrity. Our Configurable Mixed-signal ICs makes allow customers to implement custom circuits into a small programmable IC via NVM. This technology allows for fast design changes, lower cost, lower, BOM and scalability between different platform models. A typical GreenPAK implementation can easily displace 20 to 30 discrete components. We have shipped close to four (4) billion parts in the last six (6) years.”

Point-of-load DC-DC converter

Power management solutions occupy a special place in electronic design, influencing not only reliability but above all production costs.

The specifications of the power system often changed during the design cycle itself. With a system based on discrete components, this may require a redesign of the printed circuit board to accommodate the increased (or reduced) power supply space required.

Power module suppliers are responding to the need for more power rails to drive very different current levels on printed circuit boards (PCBs) with a new type of low current power regulator. These so-called non-isolated Point Load Voltage Regulators (POLs) are small devices, designed to be placed close to load circuits on boards that provide current over a wide operating range. The use of modules at the point of the load has grown steadily over the past few years, and there are now many suppliers who can offer standard solutions that meet various power supply needs at competitive costs.

By implementing a discrete component solution, the study and analysis of interference could become problematic and still take up a lot of time, with a high level of risk of failure falling to the designer.

The current trend in the semiconductor world of increasing the level of integration has led to the creation of power integrated circuits that include protection and control functions, with a consequent reduction in the number of peripheral components required, which in turn translates into a reduction in both costs and space requirements.

The new µPOL DC-DC converter series offers full integration with various versions that differ from supplier to supplier. With dimensions in the order of mm, the new solutions reduce the external components required, maintaining the highest possible performance while offering a simplified design for easy integration.

Power and thermal management

Dialog Semiconductor and TDK combine a technology that offers a reduction in lead time and accelerates the development time of electronic boards. TDK’s µPOL solution leverages advanced technology packaging techniques such as embedded semiconductor substrate (SESUB) for cohesive integration of the 3D system in a smaller, lower-profile format. This integration allows TDK to provide higher power density and ease of use.

“Any board that is size constrained and requires higher reliability, scalability, lower cost. Also, the increased flexibility provided by the GreenPAK device in configuring the design for application-specific timing/safety features. Examples include: Turn ON/Turn OFF Times, Number of Channels, Configurable UVLO / OVLO Thresholds, Fault Detection Logic, etc. This flexibility provides a lot of value to our customers over ASICs,” said Ammar.

Dialog’s GreenPAK devices serve as ultra-small power management integrated circuits. They are designed to create “Flexible Power Islands” (FPIs), where the user can customize their power system for individual application requirements.

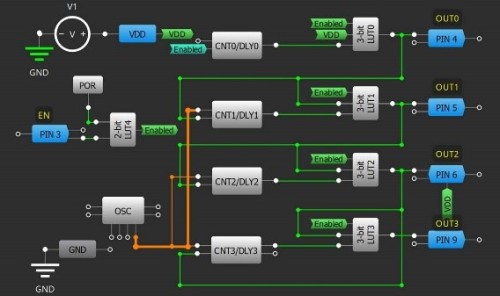

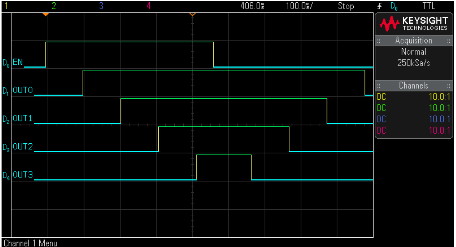

In figure 1 (and figure 2) a simple power sequencer is shown with four (4) rails powering up and down using an enable signal, but it does not react to intermediary rail crash or other failure issues. This simple circuit shows a minimum requirement of about 14 discrete components (i.e., resistors. capacitors, logic blocks) – a number that may increase depending on if more function is needed. “Through our collaboration with TDK, users can separate sequencing designs based on specific MCUs, the devices are custom-built for different MCUs as well as the number of power rails,” said Ammar.

Used for control signals, the GreenPak family typically requires less than 25MHz frequency. Sometimes they are DC signals with very low stand by power (<1uA), in which case there will not be any thermal issues, but it will definitely help reduce the board size to eliminate some of the discrete components. “With TDK power converters, they will be the primary source of thermal heat generation. Assuming they have an adequate thermal management implementation on their chip to accommodate for small PCBs, the system should work fine since we only replace discrete components,” said Ammar.

There are many challenges in designing power systems for portable and wearable devices. With each successive generation, power systems become increasingly complex, yet the overall board area dedicated to power components continues to reduce in size, smaller and smaller. Control, sequencing, and power regulation are required to support nearby loads and ensure an easy design to meet stringent time-to-market requirements.