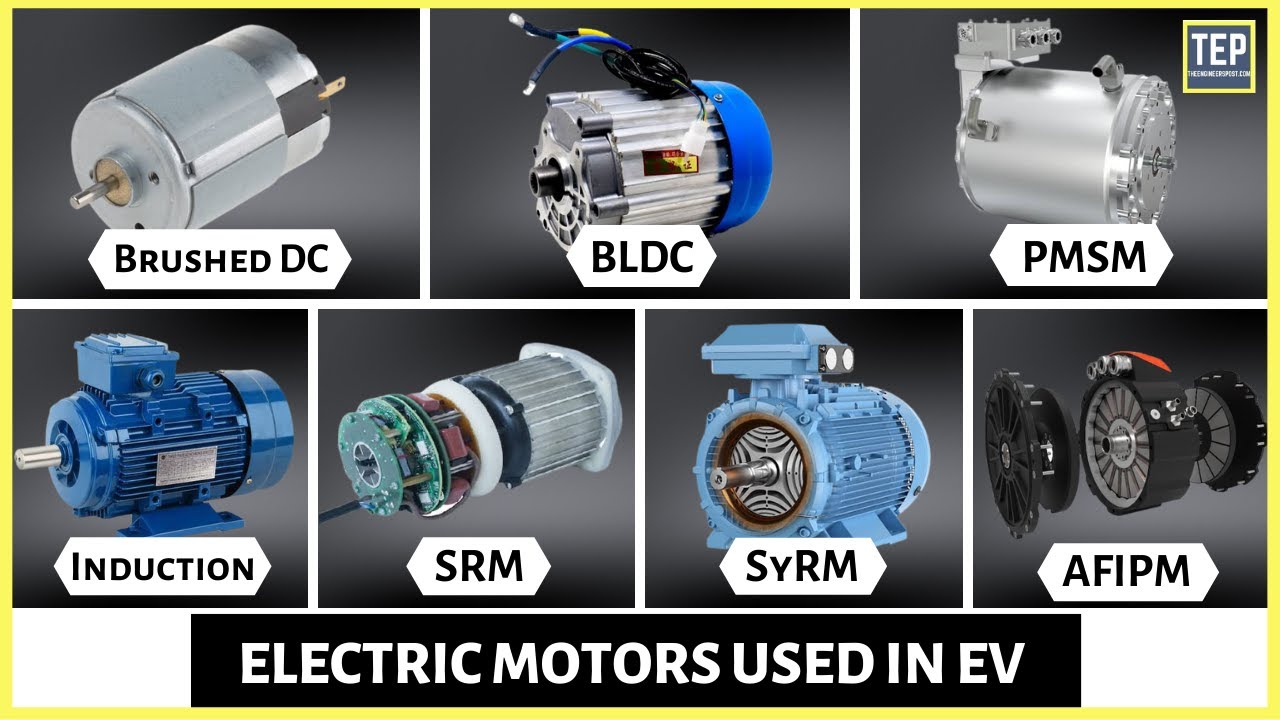

Overview: This article will review some of the different electrical machines used in electric vehicles. Each electric machine serves a specific purpose; therefore, many design considerations are necessary when designing an electrical machine for electric vehicles.

Electrical machines are essential in electric vehicles (EVs) for transforming electrical energy from the batteries into mechanical energy that powers the vehicle. There are two basic kinds of electrical machines found in EVs:

Electric motors: The wheels of the car are propelled by electric motors. They function by converting electrical energy into rotating mechanical energy utilizing electromagnetism's basic principles.

Electric generators: These are used to refuel the vehicle's batteries. They function by converting mechanical energy into electrical energy utilizing the electromagnetism principles.

The type of electric motor used in an EV depends on how it is built and what it will be used for. For example, smaller EVs may have brushless DC motors, while larger EVs may have three-phase AC induction motors. Overall, the job of electrical machines in EVs is to provide a reliable and efficient way to turn electrical energy into mechanical energy and vice versa. This lets the vehicle be powered and recharged as needed.

Fig. 1 Various motors used in Electric Vehicles. Source: YouTube: The Engineers Post

Induction Machines

Electric vehicles (EVs) often use three-phase AC induction motors because they are reliable, robust in structure, and cheap. They are also relatively maintenance-free. Using the principles of electromagnetic induction, the rotor (the part of the motor that turns) is made to carry a current. In electric vehicles (EVs), the induction motor is usually connected to the wheels through a reduction gear. This gear is used to change the torque and speed of the motor to fit the vehicle's needs.

In EVs, induction motors have a lot of good points. They are easy to use and durable, and they can work at a wide range of speeds and loads. They also have a high power density and work well, which makes them good for a wide range of EV uses. But induction motors in EVs also have some problems. At low speeds and with light loads, they tend to be less efficient, and they can make a lot of electromagnetic noise, which can be a problem in some situations. Fig. 1 shows the motor of a Tesla Model S where the rotor is made of copper.

Wound Field Induction Motors

Wound field induction motors, also called wound rotor induction motors, are a type of three-phase AC induction motor that is often used in electric vehicles (EVs). Like other induction motors, they use electromagnetic induction to cause a current in the rotor, which is the part of the motor that turns. The main difference between wound field induction motors and other induction motors is that the rotor of a wound field induction motor is made up of a series of windings (coils of wire) that are connected to external resistors. This makes it possible to control the resistance of the rotor from the outside, which can be used to change the torque and speed of the motor.

Wound field induction motors are usually used in EVs when the torque and speed of the motor need to be controlled very precisely. For example, they could be used in electric vehicles (EVs) with regenerative braking systems, in which the motor acts as a generator to get energy back when the car slows down. In EVs, wound field induction motors have a lot of good points. They can give precise control over the torque and speed of the motor, which can be helpful in some situations. They are also efficient and pack a lot of power into a small space, and they can run at a wide range of speeds and loads.

But wound field induction motors in EVs also have some problems. They are harder to make and cost more than other types of induction motors. They can also make a lot of electromagnetic noise, which can be a problem in some situations.

Reluctance Machines

Reluctance motors can be used in electric vehicles (EVs). In response to a changing magnetic field, they use the laws of electromagnetic induction to make the rotor, which is the part of the motor that turns, turn. In many ways, reluctance motors are like other induction motors, but they are built a little differently. Instead of using windings (coils of wire) on the rotor to make a magnetic field, reluctance motors use a rotor with a series of magnetic poles that are magnetized and unmagnetized in a specific pattern to make the desired rotational force.

In EVs, reluctance motors can be used instead of other types of induction motors, like brushless DC motors or three-phase AC induction motors. They are good in some applications because they are efficient, have a high power density, and can work at a wide range of speeds and load conditions. But there are some problems with reluctance motors in EVs as well. They can be harder to make and cost more than other types of induction motors. They may also make more electromagnetic noise, which can be a problem in some situations.

Stator permanent magnet machines

In stator permanent magnet machines, the magnets that make a magnetic field are in the stator, which is the part of the motor that doesn't move. The rotor, which is the part of the motor that turns, usually has windings, which are coils of wire that are connected to a power source outside of the motor. When an electric current flows through the windings, it creates a magnetic field that interacts with the magnetic field of the stator. This causes the rotor to turn.

Permanent magnet rotor machines are often used in electric vehicles (EVs) because they are simple, durable, and can work at a wide range of speeds and loads. They are also very efficient and pack a lot of power, which makes them good for a wide range of EV uses. But there are also some problems with stator permanent magnet machines in EVs. They can be pricey to make, especially if the magnets are made of rare earth materials, and they can make a lot of electromagnetic noise, which can be a problem in some situations.

Field modulation machines

Field modulation machines are similar to induction motors and synchronous motors, but they have a special feature that lets the strength of the magnetic field in the stator (the part of the motor that doesn't move) be controlled. This can be used to change the torque and speed of the motor to meet the needs of a particular EV application.

Field modulation machines can be used in EVs instead of other types of electrical machines, like brushless DC motors or three-phase AC induction motors. They have some advantages in some situations, such as being able to control the torque and speed of the motor very precisely and having good efficiency and power density.

But there are also some problems with field modulation machines in EVs. They can be harder to make and cost more than other types of electrical machines. They may also make more electromagnetic noise, which can be a problem in some situations.

High speed machines

High speed machines are made to work at high speeds, usually more than 10,000 rpm, and are usually used in situations where high speeds are needed. EVs can use brushless DC motors, synchronous motors, and induction motors, which are all types of high-speed machines. What kind of high-speed machine is used in an EV depends on how it is made and what it is used for.

High-speed machines are usually used in electric vehicles (EVs) in places where high rotational speeds are needed, like in the drivetrain or powertrain. They can be used to move the wheels of the vehicle, power the electrical systems of the vehicle, or do other things as needed. There are many good things about high-speed machines in EVs. They can make a lot of power and torque at high speeds, which can be useful in some situations. They are also efficient and pack a lot of power into a small space, and they can run at a wide range of speeds and loads.

EVs, on the other hand, can't go as fast as some high-speed machines. They can be hard to make and cost a lot of money, and they may make a lot of electromagnetic noise, which can be a problem in some situations.

Summarizing with key points:

- Induction motors are stable, efficient, and affordable, making them a popular choice for electric vehicles (EVs), but there are certain factors to consider before using one.

- Wound field induction motors may be used in EVs to precisely adjust torque and speed. However, their complexity and cost may make them unsuitable.

- Due to their complexity and expense, reluctance motors may not be the ideal solution for all EV applications. The optimum electrical machine for an EV application must be carefully considered.

- Stator permanent magnet machines are dependable, efficient, and powerful, making them ideal for EV applications.

- Field modulation devices may help manage motor torque and speed in EVs. However, their complexity and cost may make them unsuitable. The optimum electrical machine for an EV application must be carefully considered.

- Due to their complexity and cost, high-speed machines may not be the ideal solution for EV applications that demand high rotational speeds. The optimum electrical machine for an EV application must be carefully considered.