In the realm of electronics and electrical engineering, precision control over electrical parameters is essential for achieving optimal performance in various applications. Two commonly used components for achieving this control are the rheostat and the potentiometer. These devices play a pivotal role in regulating current and voltage in circuits, enabling engineers and technicians to fine-tune systems to meet specific requirements. While both the rheostat and potentiometer share similarities in terms of their functionality and applications, they are distinct devices with unique characteristics that set them apart. This article delves into the intricacies of these components, exploring their differences, working principles, applications, and practical considerations.

Understanding the significance of rheostats and potentiometers necessitates an exploration of their individual features and purposes. In many cases, these devices are employed interchangeably due to their analogous functions, but a deeper examination reveals the nuances that make each component indispensable in its own right. As we delve into the world of rheostats and potentiometers, we uncover their distinctive attributes, shedding light on how they contribute to the diverse landscape of electrical engineering.

Unveiling the Rheostat

The rheostat, a sibling to the potentiometer, presents itself as a unique member within the field of variable resistors. Distinguished by its utilization of two terminals, the rheostat establishes a direct relationship between a wiper and one of its sides, thereby enabling controlled resistance manipulation.

Unlike the potentiometer, which is designed with a trio of terminals to facilitate voltage division, the rheostat's configuration is tailored for applications where a single variable resistance is paramount. By adjusting the position of the wiper along its resistive element, the resistance in the circuit can be finely tuned. This adjustment directly influences the current flow, allowing engineers to regulate and optimize the circuit's performance.

Understanding Potentiometers

A potentiometer, often called a pot, is a remarkable example of a variable resistor designed with a trio of terminals. This ingenious device is equipped with an adjustable divider and a sliding contact mechanism, rendering it indispensable for regulating voltage within electronic circuits.

At its core, a potentiometer is a specialized type of resistor that facilitates voltage division through its distinct design. Consisting of three terminals, it features an input terminal, an output terminal, and a third terminal that acts as a wiper. The wiper is ingeniously engineered to glide along a resistive track, allowing for precise adjustments to the voltage output. By controlling the position of the wiper, engineers, and technicians can vary the voltage distribution ratio between the input and output terminals, effectively modulating the voltage to meet specific requirements.

10 Distinctive Contrasts Between Rheostat and Potentiometer

Utilization and Purpose:

Potentiometer: Functioning as a component in electronic applications and a measuring device, the potentiometer finds its place in circuits requiring precise voltage adjustment.

Rheostat: Regarding changing resistance values within a circuit, the rheostat takes center stage, catering to scenarios demanding controlled resistance modification.

Composition and Makeup:

Potentiometer: Crafted from a blend of components, including resistance materials and graphite wires, the potentiometer's construction embodies a mix of specialized elements.

Rheostat: The rheostat's composition involves amalgamating diverse materials like carbon ribbons and metal films, reflecting its adaptable nature in various circuit contexts.

Functionality in Diagrams:

Potentiometer: Within diagrams, the potentiometer is a dynamic entity adept at altering voltage levels to accommodate specific circuit requirements.

Rheostat: As a current-controlling maestro, the rheostat's prowess is often harnessed to manage the flow of electric current within systems.

Primary Function:

Potentiometer: At its core, the potentiometer shines as a master of voltage division, excelling in scenarios where precise voltage distribution is paramount.

Rheostat: The critical role of the rheostat lies in its ability to dictate the flow of current, effectively governing the current pathways within a circuit.

Voltage vs. Current Configuration:

Potentiometer: Configured to supply voltage across a spectrum of systems, the potentiometer is a versatile voltage supplier.

Rheostat: In contrast, the rheostat assumes the task of managing current flow, often arranged in series configurations to control the magnitude of current passing through the circuit.

Application Diversity:

Potentiometer: Designed for applications demanding low power consumption, the potentiometer finds its niche in devices like TV and audio controllers, and even as a transducer.

Rheostat: Stepping into high-power industrial systems such as mixers and fans, the rheostat's capabilities are harnessed to control robust equipment.

Terminal Configuration:

Potentiometer: A potentiometer's trio of terminals forms the foundation of its design, each terminal playing a unique role in its voltage division functions.

Rheostat: In the case of the rheostat, one central terminal and one-edge terminal collaborate to dictate the resistance levels within the circuit.

Connection Strategies:

Potentiometer: To incorporate a potentiometer effectively, it is linked in parallel with the circuit, ensuring optimal voltage adjustment without disrupting the circuit's flow.

Rheostat: The rheostat's utility shines when integrated in series connections with other circuit components, enabling efficient control over current flow.

Voltage Division Capability:

Potentiometer: Standing as a true champion of voltage division, the potentiometer expertly divides voltage to achieve the desired output levels.

Rheostat: Unlike the potentiometer, the rheostat's prowess lies predominantly in controlling current; its design does not permit the same level of voltage separation.

Flexibility in Functionality:

Potentiometer: Leveraging its versatile design, a potentiometer can seamlessly assume the role of a rheostat when the situation demands.

Rheostat: In contrast, the rheostat is not inherently equipped to function as a potentiometer, limiting its adaptability to specific current-control applications.

In the intricate tapestry of electronic components, the distinctions between the rheostat and potentiometer emerge as essential factors that influence their respective roles and applications. From voltage division to current control, the subtleties of these devices unveil their unique contributions to the diverse landscape of electronics and electrical engineering.

Choosing Between Rheostat and Potentiometer: Matching Components to Applications

When faced with the decision of whether to opt for a rheostat or a potentiometer, it's imperative to recognize that these components boast subtle differences in specifications, shaping their suitability for various scenarios. Understanding the distinctive applications of potentiometers and rheostats is pivotal in determining their optimal use.

Rheostat Use Cases:

Adjusting Current:

A prevalent role of the rheostat lies in regulating the current flow within a circuit. For instance, it serves as an adept tool for manipulating a light bulb's brightness or modulating a motor's speed. By varying the resistance in the circuit, a rheostat grants precise control over current levels, enabling the fine-tuning of connected devices.

High-Power Applications:

Tailored to tackle formidable currents and power demands, rheostats are primed for applications necessitating robust current control. The rheostat's capabilities shine in the industrial domain, where powerful systems such as mixers and fans require meticulous current management.

Potentiometer Use Cases:

Voltage Division:

Within circuits seeking voltage division, potentiometers stand as valuable assets. Employed as voltage dividers, they yield variable voltage outputs contingent on the position of the wiper. This adaptability proves invaluable in scenarios where a fluctuating voltage output is desired.

Signal Control:

Potentiometers find their footing in low-power landscapes, deftly maneuvering signal control. In audio systems, they enable the precise adjustment of volume and tone, while in the intricate domain of electronic circuits, they seamlessly fine-tune signal levels to meet specific requirements.

Precision Control:

The allure of potentiometers is further heightened by their ability to deliver precision control. With an array of resistance values at their disposal, they cater to the exacting needs of a circuit, offering fine adjustment capabilities that translate into optimized performance.

In the broader scheme, a rule of thumb emerges: rheostats are the go-to choice for applications demanding the governance of significant currents, while potentiometers excel in scenarios necessitating voltage division, signal manipulation, and precision control. However, the choice between these components is not arbitrary; it hinges on the specific prerequisites of your circuit and the parameters you seek to regulate.

Before finalizing your decision, a prudent approach involves consulting the detailed specifications and datasheets of the components under consideration. This ensures that the chosen component aligns harmoniously with the distinctive demands of your application. By meticulously evaluating compatibility, you pave the way for an optimized circuit design that harnesses the full potential of either a rheostat or a potentiometer, leveraging their unique attributes to achieve precision and efficiency.

Working Principles:

Rheostats:

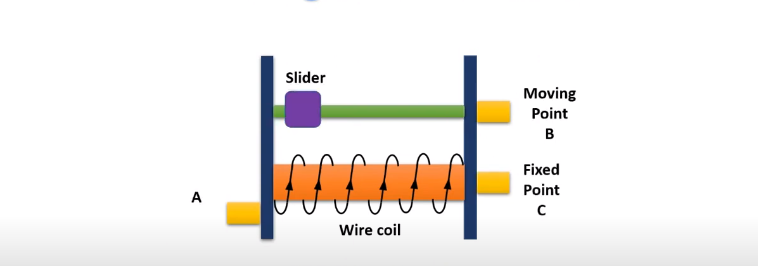

A rheostat operates on the principle of variable resistance. It comprises a resistive element, often a coil or a wire wound around an insulating core. The wiper, connected to the adjustable arm of the component, can slide along this resistive element. As the wiper's position changes, the effective resistance in the circuit is altered, subsequently influencing the current flow. Increasing the wiper's distance from one terminal increases resistance, restricting current flow, while reducing the distance lowers resistance and allows more current to pass through.

Figure 1: Working Principle of Rheostat

Potentiometers:

Potentiometers operate based on the principle of voltage division. The device consists of a resistive track with three terminals - one at each end and one at the wiper's location. When a voltage is applied across the two ends of the resistive track, the wiper's position determines the fraction of the tapped voltage. This allows for generating variable voltage outputs that are proportional to the wiper's placement along the resistive track.

.png)

Figure 2: Working Principle of Potentiometer

Applications:

Rheostats:

Light Dimming: Rheostats are utilized in lighting systems to control the brightness of bulbs or LEDs, allowing users to adjust the intensity of the light.

Motor Speed Control: In applications involving electric motors, such as fans and conveyor systems, rheostats govern the motor's speed by modifying the current flow.

Heating Elements: Devices like toasters, ovens, and industrial heaters utilize rheostats to regulate the heat produced by controlling the current through the heating element.

Potentiometers:

Audio Equipment: Potentiometers are extensively used in audio systems to control volume, tone, and balance. They enable users to finely tune the auditory experience.

Voltage Division Circuits: Potentiometers act as voltage dividers in various circuits, enabling the generation of reference voltages or adjustable output voltages.

Signal Level Control: In electronic circuits, potentiometers are employed to adjust signal levels, ensuring optimal performance and signal integrity.

Sensors and Transducers: Potentiometers serve as transducers in sensors, converting mechanical changes into variable resistances that are then translated into measurable signals.

Practical Considerations:

Rheostats:

Heat Dissipation: Due to their role in dissipating power as heat, rheostats may require adequate cooling mechanisms, especially in high-power applications.

Limited Resistance Range: Rheostats typically offer a limited range of resistance values, which can impact their suitability for certain applications requiring extreme resistance adjustments.

Potentiometers:

Tolerance and Linearity: Potentiometers might exhibit tolerance variations and non-linearity across their resistive tracks, leading to inaccuracies in the output.

Wear and Tear: Continuous usage can cause mechanical wear on the resistive track or the wiper, potentially leading to signal fluctuations or inconsistencies.

Contact Noise: In applications where precise control is paramount, the sliding contact between the wiper and the resistive track can introduce noise into the circuit.