High indoor CO2 concentration typically is the result of human presence. Our body breathes in oxygen and emits CO2, which accumulates indoors if the environment is not properly ventilated.

Moreover, the dense thermal insulation of modern buildings indirectly contributes to the increase of carbon dioxide. For example, dense windows and doors that reduce consumption and heating or cooling costs do so at the cost of reduced exchange of air with the outside. The consequence is, therefore, an increase in CO2 concentration that leads to a continuous need for ventilation. It is in these cases that CO2 sensors are often used to regulate the ventilation system.

High CO2 levels compromise human health and productivity. Combining a CO2 sensor together with air exchangers and intelligent ventilation systems allows ventilation to be regulated in the most energy-efficient and human-friendly way. In addition, CO2 sensors play an essential role in monitoring indoor air quality and can therefore be integrated into air purifiers and intelligent thermostats and other smart home products.

Carbon dioxide concentrations above 1,000 parts per million (ppm) reduce productivity and can cause drowsiness in humans. At CO2 concentrations higher than 2,000 ppm, some people start to get headaches. Let’s consider that in a closed room, such as a crowded classroom, the presence of many people and poor ventilation can produce a level of carbon dioxide up to 5,000 ppm.

The New York Times said, “The higher the carbon dioxide, the worse the test-takers did; at 2,500 ppm, their scores were generally much worse than at 1,000 ppm.” Moreover, “without a specialized sensor, you can’t realistically know how much carbon dioxide is building up while you hunker down in a small room for a long meeting.”

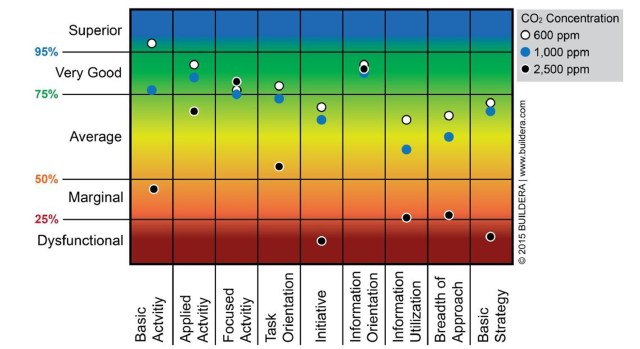

Air exchangers and intelligent ventilation systems in the commercial and residential sectors use CO2 sensors to regulate ventilation in the most energy-efficient and human-friendly way. The integrated CO2 sensor makes an enormous contribution to both air quality and energy savings. The air-conditioning electronics for a CO2 sensor also allow for monitoring the air quality trend, as well as for making decisions without relying on our senses (Figure 1).

“Public awareness for indoor CO2 levels is growing: There is an increasing number of initiatives from the public and private sector to monitor and counteract high CO2 concentrations,” said Marco Gysel, product manager of CO2 Sensors at Sensirion. “Most initiatives focus on classrooms, universities, and commercial office buildings, but there is an increasing demand for CO2 sensing for residential apartments as well. Authorities and companies are starting to realize that the reduced cognitive performance of students and workers comes at a high cost.”

Figure 1: Impact of CO2 on human decision-making performance (Image: Environmental Health Perspectives. 120(12). doi:10.1289/ehp.1104789)

Sensirion has introduced a miniaturized CO2 sensor device based on photoacoustic sensing. It’s offered in a package only 10 × 10 × 7 mm, making it appropriate for applications in IoT, consumer electronics, appliances, and the HVAC market. The sensor, designated the SCD40, can also measure temperature and humidity.

The new SCD40 sensor and photoacoustic technology

The SCD40 miniaturized CO2 sensor offers new approaches to product design and will create the basis for a wide range of new sensing applications. Sensirion’s experience has enabled it to improve its latest innovations in CO2 sensor technology, offering a new device that is smaller than a factor of seven compared to its predecessor, the SCD30. The photoacoustic detection principle reduces the size of the optical cavity used in the SCD30 without compromising performance.

State-of-the-art CO2 sensors such as Sensirion’s SCD30 are based on the non-dispersive infra-red (NDIR) optical detection principle. The use of these NDIR sensors is limited to a few applications due to their size and cost.

NDIR-type sensors are optical sensors, which are frequently used in gas analysis. The main components are the infrared source with a wavelength filter, a sample gas chamber, and an infrared detector (Figures 2 and 3). By illuminating an infrared beam through a sample cell (containing CO2) and measuring the amount of infrared absorbed by the sample at the required wavelength, an NDIR detector can measure the volumetric concentration of CO2 in the sample.

The sensitivity of a sensor based on the NDIR principle is directly proportional to the optical beam path. A large reduction of the path leads to a compromise of its performance, which limits the miniaturization potential of this technology. In addition, sensors based on the NDIR principle do not have an economic BOM structure due to their size, structure, and a large number of discrete components.