Current sensors an play essential role in many electronic applications, to improve the application’s efficiency and monitor current flow

Current sensors play an essential role in many electronic applications, allowing you to improve the application’s efficiency and monitor current flow to avoid possible malfunctions or failures.

The technological evolution undergone by current sensors over the years has led to the creation of integrated current sensors, in addition to offering high levels of accuracy and reliability, which are available in standard packages with a very small footprint. The latest generation sensors incorporate high voltage isolation features, a high degree of immunity from external electromagnetic fields and superior accuracy, making them the ideal solution for measuring AC and DC currents in industrial, automotive, smart meters, photovoltaics, DC-DC converters and inverters.

LEM’s New Digital Current Sensors

On the occasion of the recent PCIM Europe 2022, held in Nuremberg, Germany, on 10-12 May 2022, LEM announced HMSR DA, the world’s first integrated current sensor with a sigma-delta bitstream digital output. LEM, a specialist in solutions for measuring electrical parameters and a global leader in current sensors technology, intends to strengthen with this product it’s offering of digital sensors, specifically digital integrated circuits (ASICs) that include a current sensor. Primarily used on the DC side of the inverter, HMSR SMS measures AC and DC currents with high accuracy and high immunity to external interference. On the AC side, the newly launched LWSR supports a lower levelized cost of energy (LCOE).

“The great advantage of pushing in this direction is we are offering new self-isolated solutions, and also we are increasing drastically the effective resolution of the sensor we are providing”, said Clement Amilien, global product manager, the integrated current sensor at LEM.

As the latest model of LEM’s HMSR family, the HMSR DA (Figure 1) offers high resolution on an effective number of bits (ENOB) of 11 to 13 bits, features a 10MHz clock in or out, and provides significant benefits when used in applications that operate in harsh environments, where noise, distortion and interference can affect the reliability of the measurement. The new sensor has been designed to provide a complete solution to applications that require noise-free and interference-free signals in environments affected by vibrations, electric noise and electromagnetic noise. The analogue to digital converter is already integrated into the device, and different output modes are available, including single-ended CMOS, differential RS422, and LVDS.

“Unlike traditional sensors based on CMOS technology, to improve sensitivity, we are using elements that are in the third and fifth colon of the chemical table. That means we have higher costs, but we can drastically increase the output effective resolution of the sensor”, said Amilien.

The main advantages of the integrated HMSR DA sensor with digital output include superior signal quality, reduced noise, reduced cost and small size. The solution is proposed as a valid replacement for more complex and expensive systems that normally include a shunt resistor, a digital insulator and a power supply circuit.

“Compared to traditional sensors, the big advantage we are bringing on the market is a higher resolution and already digitalized output that could help to process the signal much faster. The second advantage of our self-isolated sensor is a drastic reduction of BOM space and total cost of ownership of the solution”, said Amilien.

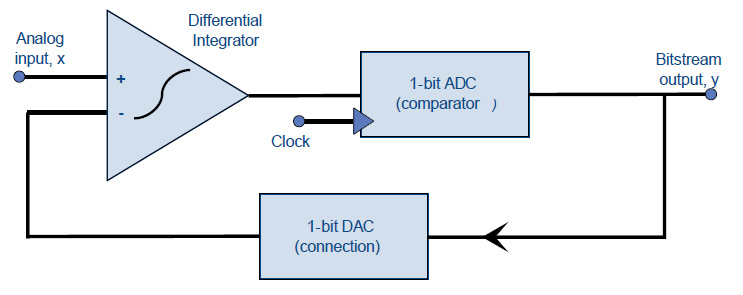

The sigma-delta bitstream output simplifies the design of the solution and is highly flexible, allowing customers to apply filters for adapting the sensor to their specific needs. Adding a sigma-delta modulator, which produces a single-bit digital output, provides additional advantages over a traditional analog type sensor, such as fewer connections required and greater flexibility the user has in choosing the output filter. This filter typically reflects the best compromise, for the specific application, between resolution and response time.

Another relevant feature of the new sensor is using an open-loop measurement technique. The sensor includes an open loop analog transducer based on the Hall effect and is capable of performing the signal processing necessary to ensure the required reliability and accuracy. The transducer represents the solution for the smallest, lightest and most economical measurement while at the same time providing very low power absorption.

The operating principle of an open loop sensor is shown in Figure 2. The primary IP current flowing through a conductor creates a magnetic field concentrated in the air gap of a magnetic circuit. The output voltage VH of the Hall effect cell is proportional to the measured current. After proper signal processing, the buffered output voltage VOUT will be an exact analog representation of the primary current. The Hall cell and the signal processing circuit are integrated within a custom integrated circuit (ASIC) to improve sensor performance. The main feature of the new HMSR DA sensor is to have added a second order sigma-delta modulator to the ASIC, obtaining a bitstream output where the density of 1’s depends on the current measured.

The LEM digital output sensor is followed by a digital filter, normally implemented by the user. The advantage of this approach is that the number of connections to the transducer is minimized, and the user can decide which filter best suits the specific application’s requirements.

“A lot of applications that were in the closed loop before are now all moving to open loop. The reason for that is the open loop can drastically improve the performance. In our product portfolio, we now have sensors with an accuracy below 2%, and some of them are good enough to replace closed-loop sensors”, said Amilien.

The new sensor targets applications, which include standalone servo drives, robotics, sewing machines, automated guided vehicles (AGVs), CNC machine tools and a range of other solutions that require high-resolution output.

The new HMSR DA sensor, capable of measuring currents from 10 to 36 ARMS and offering a dielectric strength of 4.0 kV, is LEM’s first step toward building a digital integrated current sensor roadmap. The forward-thinking company is already working on the next generation of digital integrated circuit sensors, which will offer a resolution of 14 to 16 bits and a clock operating above 20MHz.

The analog versions of the high-isolation HMSR sensor family have already been in use for several years, offering designers and power electronics technicians a series of benefits extended to the new digital model as well.

Automotive and Technology Trends

The amount of power produced per unit volume of the motor and power electronics is referred to as power density. The greater the power density, the more powerful the motor in a smaller environment. As space limits exist in practically all industrial and automotive applications, increasing power density is a vital aspect in increasing performance. Silicon carbide (SiC) and gallium nitride are two technologies permitting a significant increase in power density (GaN). These provide greater switching frequencies and are hence ideal for automotive applications where performance is critical. Over the past decade, the rising need for compact sensors capable of managing high levels of power density resulted in the introduction of integrated current sensors. Integrated Circuit Sensors detect the major current line directly using surface-mounted integrated circuits (ICs) and have become a popular technology for industrial and automotive applications due to their ability to sense relatively large currents in a small footprint.

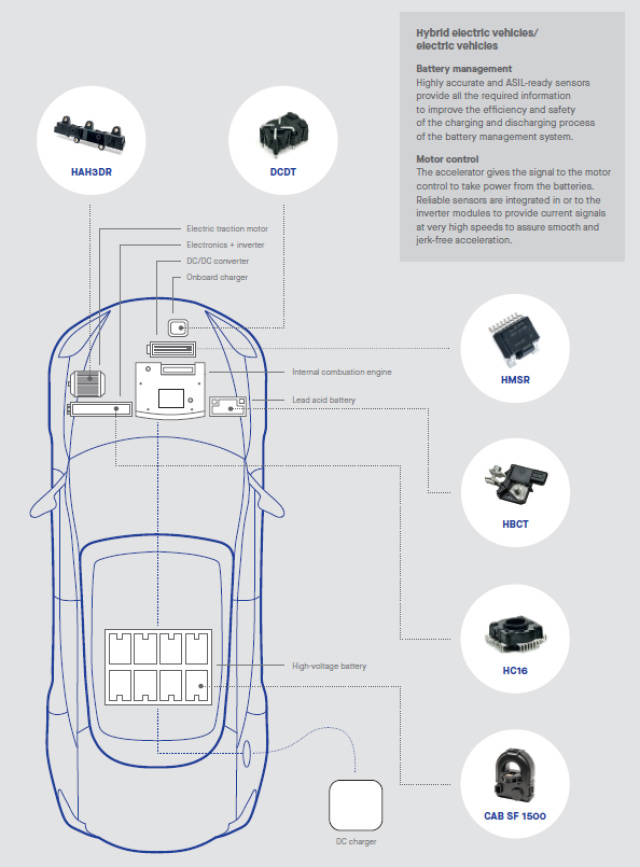

Smart grid and autonomous driving are two major disruptions led by digital revolutions to bring about smarter, greener, and more efficient ecosystems. This is creating a lot of data, communication, and the need for artificial intelligence. By 2028, 50% of annual car production will use hybrid and electric powertrains. In addition, electric and hybrid vehicles require a higher number of current sensors than combustion powertrains, spurring exponential growth in the demand for sensors. From about 125 m of current phases measured in 2020, LEM estimates that the market will grow more than four times, to reach about 450 m in 2028. LEM believes onboard chargers (OBCs), DC meters, and DC/DC converters will play a key role in the energy distribution and management of hybrid and electric powertrains. OBCs provide the means to recharge the battery using an AC socket at home or from a charging station. DC/DC converters translate high voltage coming from the battery to a lower voltage, which is then used for various onboard applications (A/C, electric power steering, etc.).

In the EU and US markets, DC metering is becoming required since regulators want users to pay solely for the power load of the vehicle’s battery, net of power line losses. Electrical safety is also becoming more crucial since the identification of current leakage protects clients in the event of a charging station failure. With ever-increasing voltage levels (up to 800 V), the battery system is at the core of hybrid and electric powertrains.

Accurate battery management systems capable of measuring the state of charge (SoC) and state of health (SoH) have become increasingly important to ensure that the driver has access to reliable information on the remaining driving range and that the battery cells are well maintained to protect the battery life.

As millions of EVs hit the road and terawatts of renewable energy capacity are being constructed, our energy system is experiencing a profound upheaval. These adjustments are necessary for decarbonizing our energy system, but they pose major hurdles. First, the intermittent nature of wind and solar energy pushes grid operators to offer system flexibility.

Second, the fast expansion of distributed energy resources (DER) is decentralizing the distribution network, increasing its operational complexity. A smarter grid is required to integrate intermittent renewable energy and DERs.

LEM delivers sensors that monitor, regulate, and automate grid operation by measuring electrical characteristics throughout the network.