Today, new power switch technologies are being widely adopted in demanding applications in which high power density, high switching frequency, and small form factor are critical requirements. The three key applications in which these new switch devices make a difference are:

- Automotive (traction inverters, DC/DC converters, and on-board chargers)

- Industrial/motor control (point-of-load supplies, uninterruptible power supplies, robotics, motor control)

- Power supply/solar (solar inverters, telecom power supplies, servers/cloud/PC power supplies)

Power switches are fabricated either using conventional silicon-based technology, such as MOSFETs and insulated-gate bipolar transistors (IGBTs), or using the more recent wide-bandgap semiconductors, such as silicon carbide and gallium nitride. Among the relevant applications, automotive is the sector that has gained more momentum in recent years, mainly due to the undergoing transition toward e-mobility and the progressive adoption of electric vehicles.

As shown in Figure 1, EVs integrate a multitude of sensors and electronic circuits, including a high-voltage bus (400 V, 800 V, or more) and a local low-voltage bus. SiC devices are replacing the Si-based counterparts in high-voltage systems, such as on-board chargers, battery management systems, main DC/DC converters, and traction inverters.

The high-voltage bus poses serious safety concerns, and it must be galvanically isolated from the low-voltage bus while still allowing the exchange of information, in both directions, between the two voltage domains.

Skyworks isolated gate drivers

Skyworks Solutions, a leading company that provides highly innovative analog semiconductors for wireless networking applications, has recently completed the acquisition of the infrastructure and automotive business of Silicon Labs. Addressing the growth in key automotive segments, including electric and hybrid vehicles, Skyworks provides high-performance and robust isolated gate drivers for silicon, GaN, and SiC power switches.

Charlie Ice, product manager at Skyworks Solutions, held a technical presentation on “Driving and Protecting the Power Switches of the Future” at PowerUP Expo 2021, talking about key gate driver requirements and protection methods for both Si-based and wide-bandgap power devices. The same topics will be presented in this article.

“Especially in EVs, we have to make sure that the high-voltage and the low-voltage sides remain isolated while at the same time ensuring they can still communicate and exchange information through that barrier,” said Charlie.

The features of the isolation device are even more important for new switching technologies, like SiC and GaN, which can achieve higher efficiencies but are more sensitive and easier to damage. Therefore, those new switching technologies require unique protections to operate both safely and reliably.

Traditionally, power-electronic systems have relied on IGBTs, the least expensive solution per watt at high power and high voltage. However, IGBTs have slower switching speed, thus limiting the efficiency of the system. That’s where SiC and GaN have both stepped in to really drive higher efficiency. One disadvantage for both is that they can’t take as many fault conditions as an IGBT can, and that’s why they need additional protection.

In high-voltage systems, for safety reasons, we must separate the high-voltage side from the low-voltage side. Often, designers decide to keep the controller on the low-voltage side so it is away from the noise and from big transients. The controller generates the pulse-width–modulation (PWM) signals and passes them across the isolation barrier to a gate driver, which basically amplifies the low-voltage PWM signal to a higher signal able to turn the power device on and off.

The two main functions performed by an isolated gate driver are to level-shift 3-V or 5-V signals to higher-voltage rails of 24 V or 30 V and to supply switching current for charging/discharging the gate capacitor. By adding a galvanic isolation barrier, this device achieves two main benefits:

- It provides input-to-output isolation for protection of the controller, and perhaps personnel, from high voltages and voltage transients.

- It helps to maintain noise-immune operation for best efficiency. High-voltage transients can disrupt operation, resulting in loss of modulation and thus efficiency.

The isolated gate driver can be safely used to switch even high-power switches, such as silicon or superjunction MOSFETs, IGBTs, and wide-bandgap switches like GaN and SiC. Isolated gate drivers are available in many flavors: single-channel, dual-channel, and ones that can generate a high-side and a low-side signal from a single PWM input.

“I typically find that many automotive systems use single-channel drivers because they make the board-layer layout easier; however, dual-channel drivers and high-side/low-side drivers are very popular in power supply systems,” said Charlie.

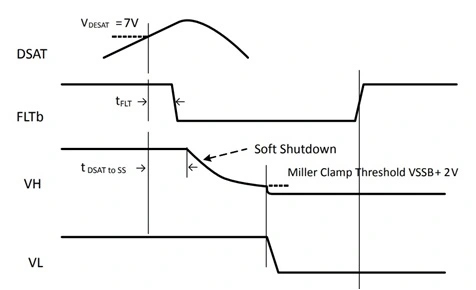

Regarding protection, one of the key methods is the Miller clamp. Its function is to monitor the voltage on the gate, and if it gets too high, it clamps it. Basically, it’s an active monitor to ensure the gate is always off. However, Miller clamp protection is not enough for SiC and GaN power devices, which are more sensitive and get damaged more quickly. The other feature we need to add for driving SiC or GaN devices, improving their protection and longevity, is desaturation detection and soft shutdown.

In a high-power system, such as a traction inverter, it’s not uncommon that power devices experience a momentary overcurrent condition. In this case, an isolated gate driver with desat detection can monitor the voltage (VCE) across the power switch. If it detects too much voltage across it (see Figure 2), which would indicate a fault condition, it automatically shuts it off in a very safe way, also known as soft shutdown. However, it is important to set the device off quickly enough to avoid being damaged. Here, we can see how switching devices behave differently. An IGBT, for instance, needs to be turned off within 3 µs, while a SiC device needs to be shut down within 1.2 µs and a GaN device within 200 ns.

“These are the two key techniques — Miller clamp and desaturation detection — that have become really critical for driving SiC and GaN successfully and making the system reliable and, in many ways, safe,” said Charlie.